There are several types of pyrolysis reactors available. There are Fixed pyrolysis reactors, Rotary pyrolysis reactors, and Continuous tyre pyrolysis plants. In this article, we’ll explore the differences between these types of reactors. To make the most informed decision about which model is right for your needs, consult a pyrolysis equipment supplier. Whether you’re looking for a horizontal or vertical condenser system, Beston can help you decide what type will work best for your needs.

Irrotational Pyrolysis Reactor

Irrotational pyrolysis reactor for sale is a process for converting waste products into useful fuels, such as diesel. The oil produced by this process is primarily comprised of aromatic compounds, which cannot be burned as diesel. In addition to being useful as fuel, the oil can also be used for the production of other materials, such as tyres. Here, we will take a look at the various types of pyrolysers that are available for sale.

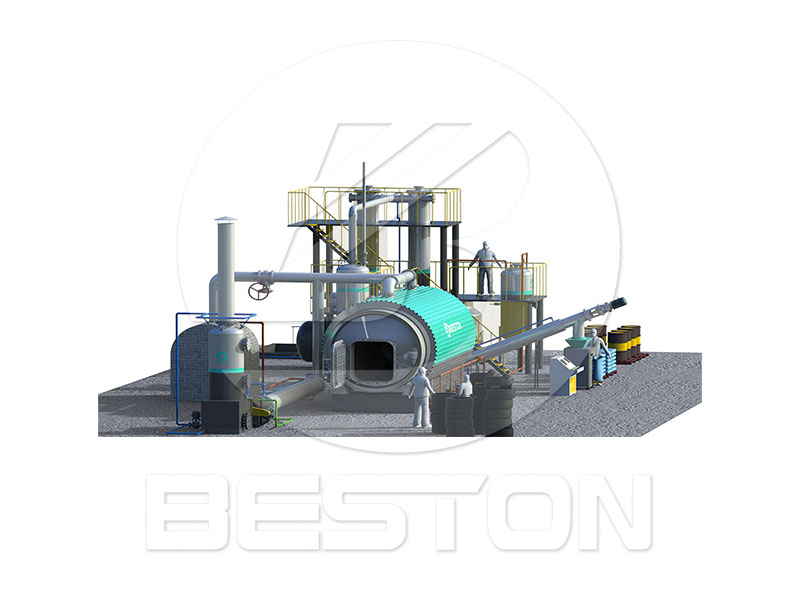

In addition to pyrolysis equipment, the reactor system includes a main furnace, a base, a casing, and a driving device. The main furnace rotates under the driving device, absorbing heat. Once the temperature reaches a specific threshold, raw materials begin to crack and release oil gas. The material used in the reactor determines how long the reactor will last, as well as how well it performs in pyrolysis.

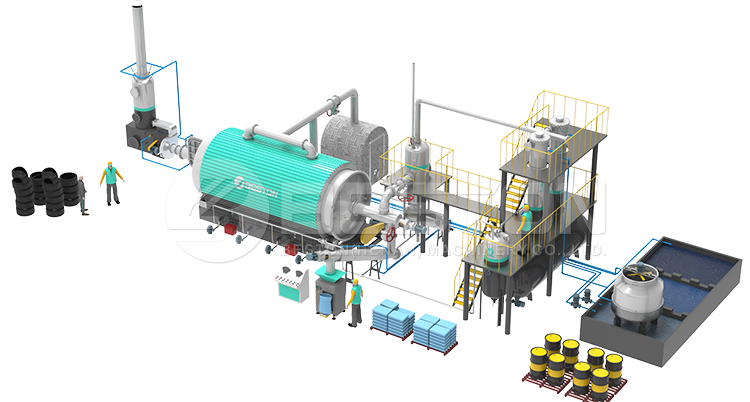

Fixed Pyrolysis Reactor

If you are in the business of pyrolysis, a fixed pyrolysis reactor is an essential piece of equipment. A good-quality reactor will save you from the hassle of repair and maintenance. Beston makes three types of reactors for sale, which can process between 6 and 20 tons of waste per day. Here is some information about each type. For starters, each type is suitable for a different application.

Beston pyrolysis plant for sale uses advanced technology and design, and is the ideal choice for companies that have massive tyre waste. It uses the same pyrolysis process to break waste materials and produce liquid fuel oil. Beston pyrolysis reactors are designed to operate simultaneously and at low energy costs. This allows customers to reduce their fundamental cost and maximize output, resulting in more profit and less pollution.

Rotary Pyrolysis Reactor

When looking for a rotary pyrolysis reactor for sale, you should first look for a suitable site. While a central location is a better option, a remote location will minimize construction costs and traffic concerns. Once you have chosen the site, you can start construction, such as building a stove and wastewater pool. Then, you can design the plant to fit a real-life location.

Depending on the material you’re processing, a rotary pyrolysis reactor will produce a variety of products. Oil produced during the pyrolysis process can be sold directly or reprocessed into diesel or gasoline. Oils extracted from waste tires are useful fuels for vehicles and other equipment. Oil from waste tires can be distilled into qualified diesel for engine oil for heavy machinery. And if you’re in the market for a used rotary kiln, consider auxiliary equipment, like de-dusting equipment. Get pyrolysis plant cost here.

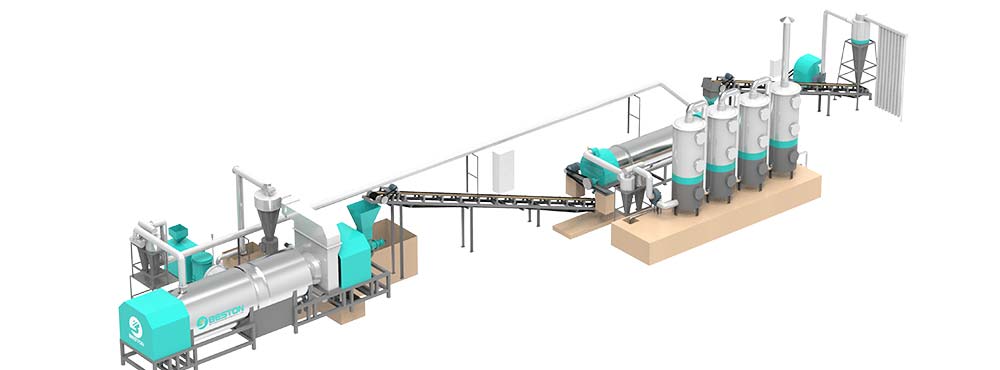

Continuous Tyre Pyrolysis Plant

A Continuous tyre pyrolysis plants for sale includes a number of different parts that work together to make the process efficient and eco-friendly. The main part of the process is the reactor, which heats up the tyres by using a combination of fuel oil, LPG, or natural gas. During the heating process, the reactor rotates 360 degrees. As a result, the tyres begin to crack and emit oil gas. Once the oil gas reaches a certain temperature, it is condensed and discharged, resulting in liquid fuel oil. During the processing, the remaining non-condensable gas is recovered and used for other purposes.

The Beston continuous waste tyre pyrolysis plant has a daily capacity of 16 to 20 tons and utilizes a sealed reactor. It can produce more oil and gas than other types of pyrolysis plants. The Beston continuous plant also offers customized installation services, ensuring the tyre pyrolysis equipment is installed properly and operates smoothly. A Beston technician is also on hand to help you get started and train your employees.