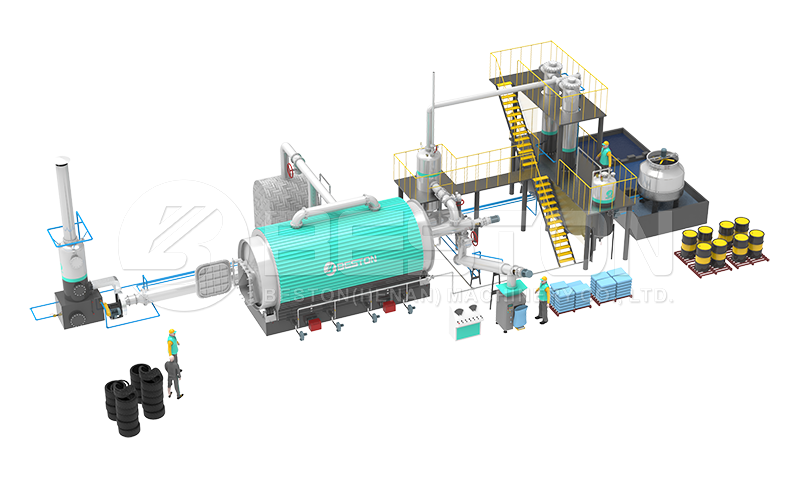

Using pyrolysis technology, tire pyrolysis plants built by Beston Company can refine oil from rubber, plastic and other organic solid litters. Pyrolysis is a thermochemical breakdown of organic substance in the deficiency of oxygen at a raised temperature. It comprises the concurrent transformation of the physical stage the chemical make-up and is lasting. The plant is appropriate for all types of rubber products.

The end products of tyre pyrolysis plant are thirty-five percent carbon black, forty-five percent tire oil, five to eight percent fuel oil which can straightly be sold since it can be utilized in restaurants, bathing centers, and boiler combustion. The carbon black product can be sold as fuel and also used in refining processing equipment. A tire pyrolysis plant is a full system. Significant apparatus comprises of a water seal system, rotating cracking furnace, dynamic & static seals, multi-stage separator among other devices. The entire pyrolysis plant is designed adequately with elevated automation and ideal secure facilities conforming to the high habitat standards.

A waste tire recycling plant can play a significant role in reprocessing resources that are already existing. They utilize worn out tires to generate resources such as pyrolysis oil which is usually applied as a furnace oil replacement. Carbon black, steel wire scrap can also be reprocessed and used in the steel factory and pyrolysis gas. Recycling of refuse tires can reduce the pressure on the environment to recycle human waste alongside lowering the need to buy furnace oil, which may grow the necessity of extracting oil. However, the surroundings of the environment should not be the only beneficiary of oil extraction. Business people possessing and operating such plants must also earn financially from tires recycling.

Tyre recycling plant cost is one of the many determinants of whether reprocessing businesses are valuable. There are incredibly several types of machines that provide investors variety and choices. Here are several elements that determine the cost of tire pyrolysis plant to help you decide what kind of plant is most appropriate for yourself.

Automation Level

Concerning the level of automation, there are several types of tire recycling plant for sale. They include:

Continuous pyrolysis machine

This type of plant can perform automatically, the feeding and discharge of output. Furthermore, it can run its operation for a while without the requirement for an opportunity to cool it. However, it can necessitate to having a gashing machine to reduce the real magnitude of the tires being fed.

Batch pyrolysis machine

This type of pyrolysis plant can operate every component of the feeding and gather the output deposit manually. Additionally, it does not require downtime for cooling.

When comparing the above two types of tire pyrolysis machines, it can be discovered that the continuous pyrolysis machine has complex systems making it remarkably more costly than the intermittent one. Furthermore, it can provide more functional run time and productivity, thus processing more tires.

Tonnage Output

The tonnage processing volume for the tire pyrolysis is another element that determines the cost of tyre pyrolysis plant. The better the size of your plant to reprocess refuse tires, the vast the price. Usually, a five-tonne machine may cost everything from twenty-five thousand to ninety thousand, based on other elements. Closely connected to this is the volume of oil the plant can remove from your refuse tire. The high the cost of removal (usually varying between thirty percent to fifty percent) considerable costly the plant will be. Other expenses that determine the total price of refuse tire pyrolysis plant involve the value of plant installation and transport expenses.

Conclusion

Currently, waste tires severely pollute our habitat. How to reprocess these tires has become an important topic. Pyrolysis is an environmentally friendly technology for refuse tires reprocessing. The reprocessed waste tires are transformed into carbon black, steel wire, and fuel oil.