Biochar is increasingly gaining attention as a powerful climate solution, not just for its soil-enhancing properties but for its ability to lock carbon away from the atmosphere. But how much carbon can one ton of biochar actually sequester? While the answer depends on multiple factors, including the feedstock, production conditions, and application methods, scientists estimate that each ton of biochar can offset between 2.2 to 3.5 tons of CO₂ equivalent. This makes biochar a valuable component in the arsenal of tools to combat climate change.

Understanding Biochar’s Carbon Footprint

To fully appreciate biochar’s carbon offset potential, it’s important to consider the life cycle of carbon in biomass. When organic materials such as wood, crop residues, or manure decompose naturally or are burned, they release stored carbon as CO₂ into the atmosphere. However, when these materials undergo pyrolysis—a process that thermally decomposes biomass in the absence of oxygen—the carbon becomes fixed in a solid form, creating biochar. This stable carbon can remain in the soil for hundreds to thousands of years, significantly slowing the carbon cycle.

Why the Production Method Matters

The efficiency and impact of carbon sequestration depend heavily on how the biochar is produced. A high-quality biochar production machine ensures a clean and controlled pyrolysis process, minimizing emissions and maximizing carbon retention. By optimizing temperature, heating rate, and residence time, modern equipment can produce high-carbon content biochar with consistent properties, making it more effective for carbon capture.

Biochar vs. Other Carbon Offset Methods

Compared to other methods like afforestation or carbon capture and storage (CCS), biochar offers unique advantages. Trees take decades to grow and store carbon, while biochar provides an immediate and measurable reduction. Moreover, unlike CCS, which requires significant infrastructure and energy input, biochar can be produced locally using existing biomass and a biomass pyrolysis plant. This decentralized model makes biochar more accessible to communities around the world, particularly in regions with abundant agricultural waste.

Soil Benefits That Enhance Sequestration

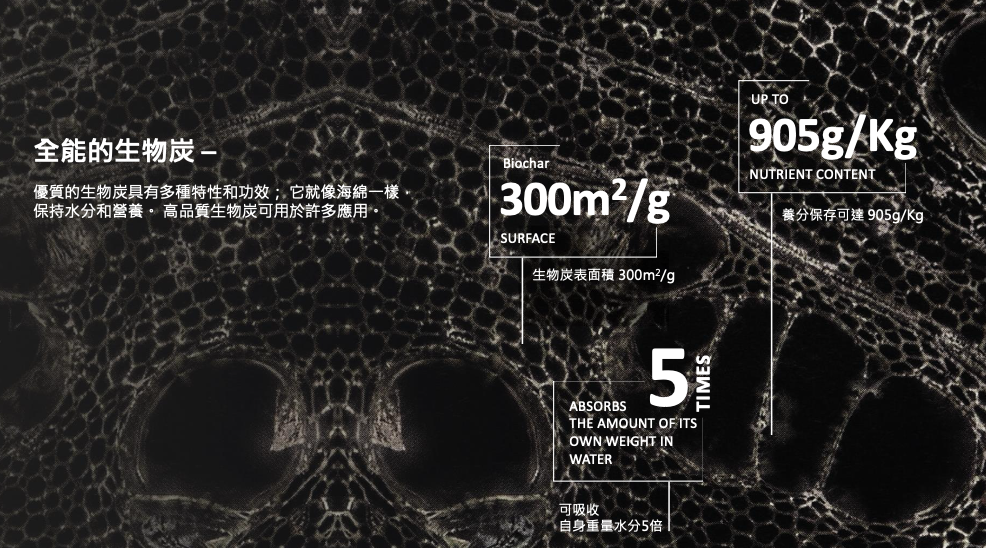

Beyond direct carbon storage, biochar also improves soil health, which indirectly boosts carbon retention. By increasing soil aeration, water retention, and microbial activity, biochar enhances plant growth and organic matter accumulation. This leads to greater carbon input to the soil from root biomass and plant residues. When biochar is integrated into regenerative farming practices, the synergy can significantly amplify total carbon sequestration.

The Role of Scale in Climate Impact

While the numbers per ton are promising, the global impact of biochar hinges on scale. If widely adopted, biochar could sequester hundreds of millions of tons of CO₂ annually. Researchers estimate that converting just 10% of the world’s crop residues into biochar could lock away over 1 billion tons of CO₂ each year. That’s equivalent to taking over 800 million cars off the road. For this vision to become reality, investment in infrastructure, such as efficient wood pyrolysis machine and logistics, is essential.

Comparing Feedstocks and Yields

Not all feedstocks produce the same amount or quality of biochar. For example, hardwoods generally result in a higher yield and more stable carbon than softwoods or agricultural residues. The density and composition of the raw material influence both the carbon content and the physical structure of the resulting biochar, which in turn affects its performance in soil applications.

A wood to charcoal machine can efficiently convert forestry waste into biochar, delivering both carbon savings and valuable by-products like syngas and bio-oil. Agricultural waste, such as rice husks, can also be transformed using a specialized rice hull carbonizer, creating a carbon-rich product while solving waste disposal challenges in farming communities.

Economic and Environmental Co-Benefits

Biochar’s value goes beyond carbon. It reduces methane emissions from decomposing biomass, enhances crop yields, and minimizes fertilizer runoff. In developing economies, small-scale pyrolysis units can create jobs, boost food security, and turn agricultural waste into profit. The creation of carbon credits for biochar projects is also gaining traction, providing a financial incentive for climate-smart practices.

Conclusion: A Scalable Climate Solution

One ton of biochar can indeed have a profound impact—offsetting up to 3.5 tons of CO₂ while simultaneously regenerating soils and reducing waste. With modern technologies like biochar production equipment and sustainable feedstock conversion systems, the future of biochar looks promising. As the world searches for scalable, nature-based climate solutions, biochar stands out as both a mitigation tool and a catalyst for sustainable development. The key now lies in scaling its production, integrating it into policy frameworks, and promoting its benefits worldwide.