The waste to energy processing plant becomes more and more important. Garbage disposal is one of the things that not so many people are comfortable talking about – but is a crucial step in every business. If you’ve been wanting to minimize your trash, and make the most out of your garbage by making a little bit of extra money with it, considering using waste to energy machine might just be your best bet. Besides, take biomass pellet plant to recycle biomass waste.

What Happens In A Waste To Energy Processing Plant?

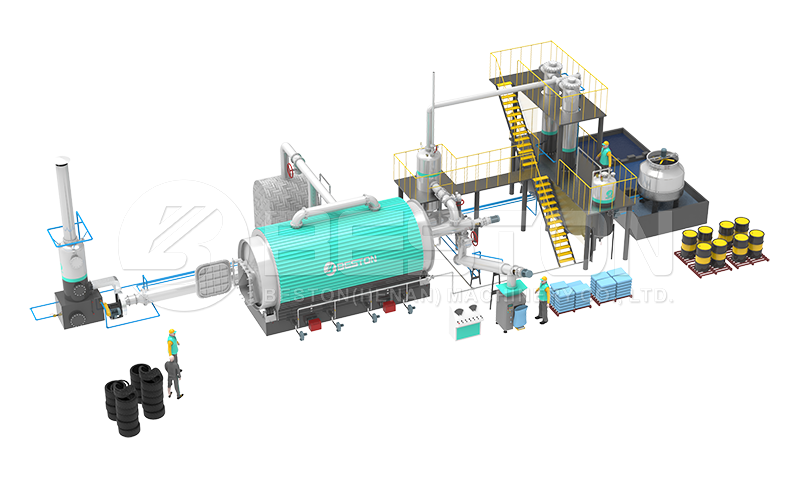

Mainly, this plant allows you to efficiently separate materials, from plastics to aluminum, to PET bottles, metals, papers and glass. Separating all of these allows you to get rid of the trash that can be sold for recycling, while the others can be converted to energy. Either way, it’s a win-win situation for businesses as this is one of the easiest and best ways to dispose of trash, get money from it, or make use of it as a source of energy. Accordingly, you should find a competitive waste recycling machine price. In addition, some customers will invest paper pulp moulding machine to make trays from paper waste.

We are all aware that many companies are trying their best to segregate their trash according to category. While the efforts of everyone in the company shouldn’t be overlooked, sometimes, it’s just way better if and faster if machines are used for this. These machines are separately purchased, which is a good investment by the way, or can be done in a waste to energy processing plant.

The Process

While the process of these processing plants may generally vary, here’s what “usually” happens when you send in your trash for disposal and/or energy conversion:

1. Garbage is fed to the platform. This is the first machine that the garbage will have to go through – there’s nothing much that goes through here, but this makes sure that the garbage is fed properly and evenly on the feeder. This is done to ensure that materials will smoothly go through the next round of machines/platforms.

2. Once it’s fed to the platform, it’ll go through a series of different sorting devices. These devices will sort plastic and other materials and would have to go through various machines to ensure accuracy. With this method, four different kinds of waste are typically the end result.

3. As soon as the garbage has been sorted out, some of the materials can be sent to third-party companies for selling. Metal, for instance, can be immediately sent to other industries.

5. Remaining materials will then be sent to another machine to turn into energy.

If you haven’t utilized these types of processes yet, you should start exploring this option as a business. Using waste to energy processing plants is a sustainable way of getting rid of trash, recycling and minimizing garbage (and the Earth will thank you for that), as well as utilizing every single bit of trash that’s possible to be used for energy conversion. It’s a great investment that all types of businesses can take advantage of. When you wanna get a waste to energy machine, get a free quote from https://bestonmachinery.com/sewage-sludge-carbonization-plant/.