In the quest for sustainable and eco-friendly solutions, the pyrolysis of wood has emerged as a remarkable process. This ingenious method allows us to transform wood, one of nature’s most abundant and renewable resources, into valuable products such as charcoal. At the heart of this transformative process lies the wood charcoal making machine.

The Raw Materials

Abundant Wood Resources

Wood is a quintessential raw material for wood charcoal making machine to pyrolysis, celebrated for its renewable nature. Trees have long been an integral part of our ecosystem, and through sustainable forestry practices, we can ensure a continuous supply of this invaluable resource.

Various Wood Types

Different wood types provide unique characteristics to the end product. Hardwoods like oak and hickory yield charcoal with higher density and longer burn times, perfect for grilling and smoking. Softwoods such as pine offer a lighter charcoal suitable for quick ignition.

Agricultural Residues

In addition to traditional wood, agricultural residues like sawdust, rice husks, and coconut shells have become popular raw materials for pyrolysis. These byproducts are often overlooked and, if not repurposed, can contribute to environmental issues. Pyrolysis turns them into valuable resources.

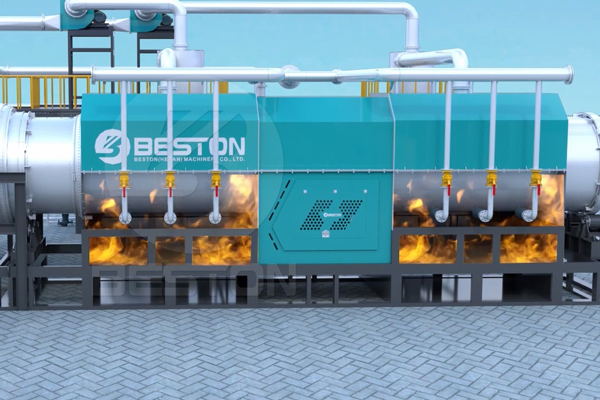

The Pyrolysis Process

Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. It involves subjecting wood or biomass to high temperatures (typically between 300°C to 800°C) within the wood carbonizing machine. This controlled environment causes the organic compounds in wood to break down into charcoal, bio-oil, and syngas.

Charcoal

The main product of wood pyrolysis, charcoal, has various applications. From traditional uses in grilling and cooking to industrial purposes like activated charcoal for water filtration and soil improvement, charcoal is versatile and in high demand.

Bio-Oil

The bio-oil extracted during pyrolysis is a valuable resource for producing biofuels and chemicals. Its potential to replace fossil fuels is a driving force behind ongoing research and development.

Syngas

Syngas, a mixture of hydrogen and carbon monoxide, is another byproduct. It can be used as a source of clean energy, contributing to reduced greenhouse gas emissions.

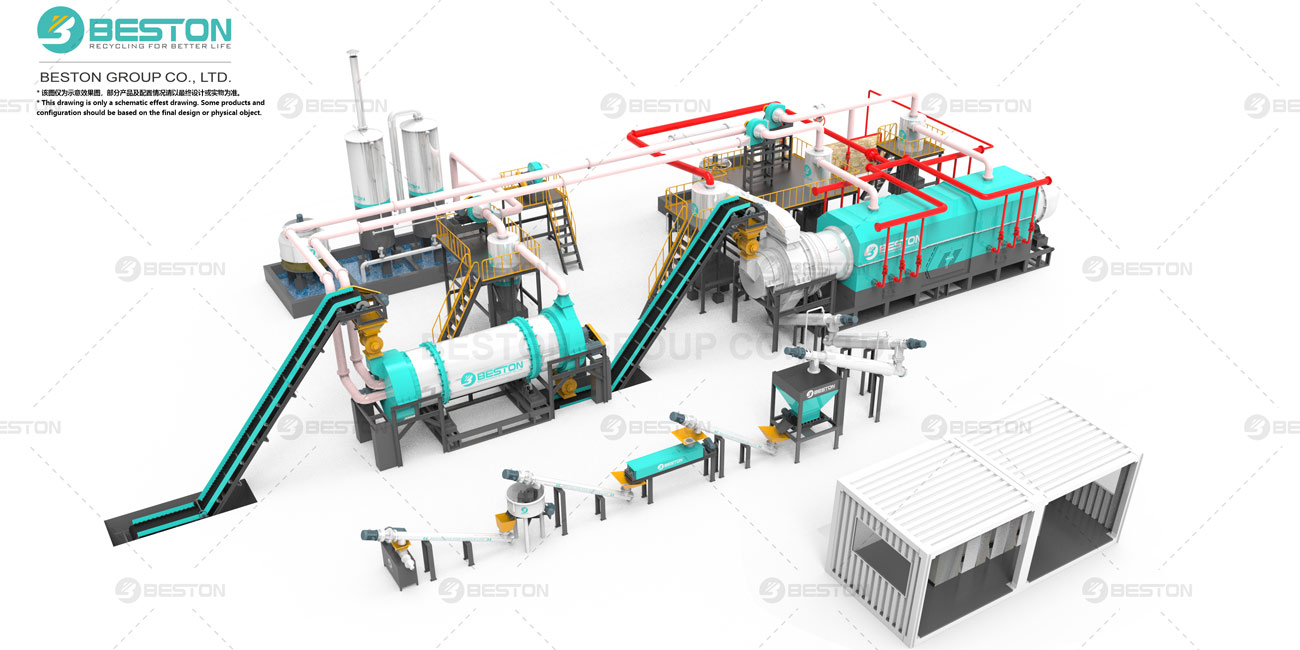

The Wood Charcoal Making Machine

Pyrolysis Reactor

The heart of the wood charcoal making machine is the pyrolysis reactor, where the raw materials undergo the thermal decomposition process. This reactor is designed to provide optimal conditions for pyrolysis while ensuring safety and efficiency.

Gas Recycling System

To minimize waste and environmental impact, modern wood charcoal making machines include gas recycling systems. These systems capture and reuse the syngas produced during pyrolysis, enhancing the overall energy efficiency of the process.

Cooling and Condensation

The bio-oil produced during pyrolysis is hot and in vapor form. Cooling and condensation systems are integrated into the machine to convert the vapor into liquid bio-oil for easy storage and further processing.

Charcoal Collection

The final charcoal product is collected and stored in a controlled environment to maintain its quality and prevent contamination.