In the ever-evolving landscape of sustainable technology, the charcoal maker machine has emerged as a transformative solution, reshaping the way we produce charcoal. This ingenious piece of equipment combines innovation with eco-friendliness, offering an efficient and environmentally responsible alternative to traditional charcoal production methods. In this comprehensive exploration, we will delve into the intricate workings of the charcoal maker machine, its key components, and the impact it has on the charcoal industry.

The Essence of the Charcoal Maker Machine

Before we dive into the technical aspects, it’s essential to understand the fundamental concept of the charcoal maker machine. At its core, this machine is designed to convert organic materials, primarily wood, into charcoal through a process known as pyrolysis. Pyrolysis is a thermochemical decomposition process that occurs in the absence of oxygen. It involves subjecting organic materials to high temperatures, causing them to break down into charcoal, gases, and liquids.

The charcoal maker machine takes this age-old concept and elevates it with modern engineering, resulting in a more efficient and sustainable charcoal production process.

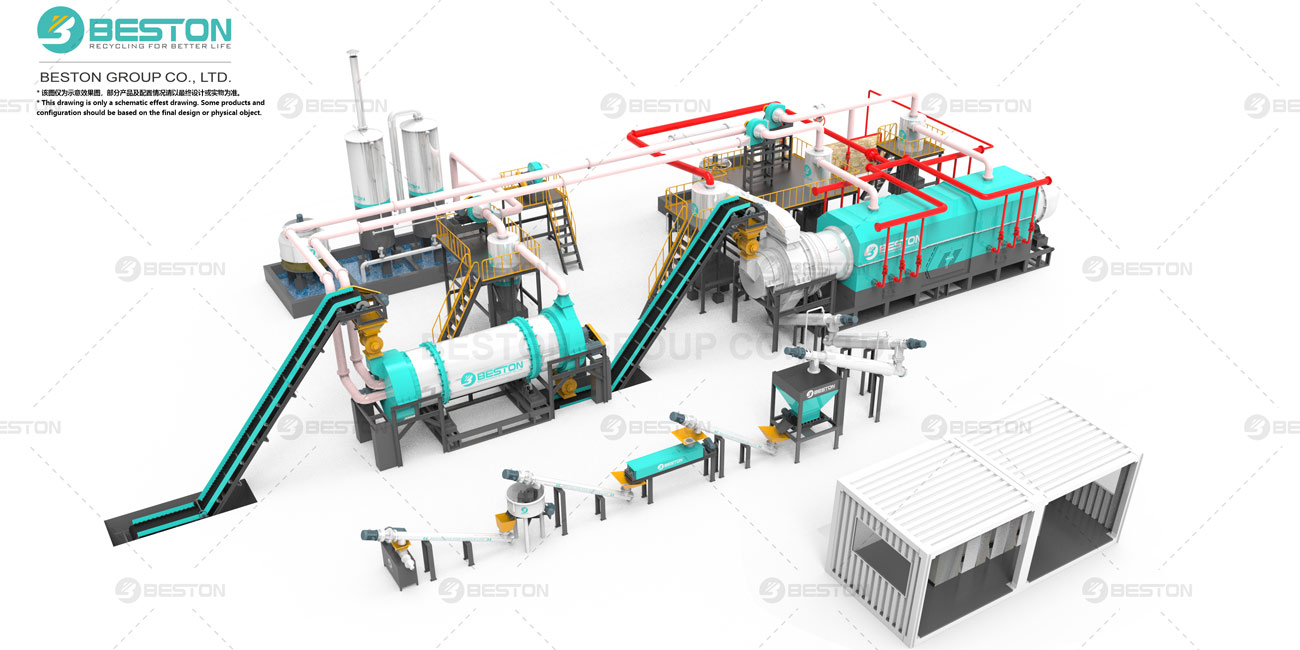

The Components of a Charcoal Maker Machine

To appreciate the efficiency and functionality of the charcoal maker machine, let’s take a closer look at its core components:

- Feedstock Feeding System: This is the entry point for the raw materials, typically wood chips or sawdust. The feeding system ensures a continuous supply of feedstock into the machine.

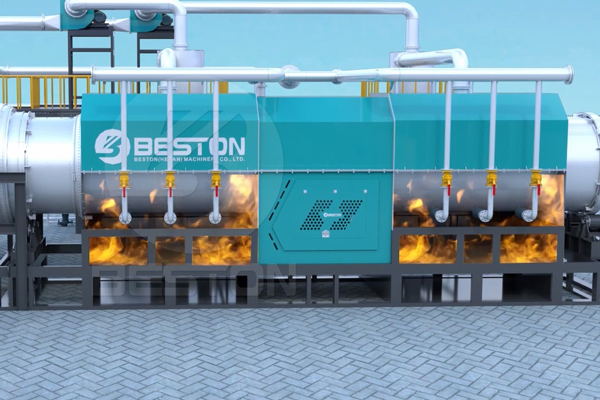

- Pyrolysis Reactor: The heart of the machine, where the pyrolysis process occurs. It is designed to withstand high temperatures and is where the transformation of wood into charcoal takes place.

- Heating System: A critical component that provides the necessary heat for pyrolysis. It can use various heat sources, including electricity, gas, or biomass, depending on the machine’s design.

- Cooling and Condensation System: After pyrolysis, gases and vapors are produced. The cooling and condensation system helps convert these gases into liquid form, allowing for their collection.

- Charcoal Collection and Discharge: The newly produced charcoal is collected and discharged from the machine, ready for further processing or packaging.

- Control and Monitoring System: Modern charcoal maker machines often come equipped with advanced control and monitoring systems that ensure precise temperature control and process optimization. Get charcoal machine price here.

How the Charcoal Maker Machine Works

Understanding the operational process of the charcoal maker machine is essential to appreciate its efficiency:

- Feedstock Loading: Wood chips or sawdust are loaded into the machine’s feeding system, which continuously supplies the raw materials to the pyrolysis reactor.

- Pyrolysis: Inside the reactor, the feedstock undergoes pyrolysis as it is exposed to high temperatures in the absence of oxygen. This thermal decomposition results in the formation of charcoal.

- Gas and Vapor Conversion: Gases and vapors produced during pyrolysis are channeled through the cooling and condensation system. Here, they are converted into liquid form, primarily pyrolysis oil.

- Charcoal Collection: The newly formed charcoal is collected and discharged from the biochar making machine. Depending on the design, it may require additional processing steps to produce the final charcoal product.

Advantages of the Charcoal Maker Machine

The charcoal maker machine offers several compelling advantages over traditional charcoal production methods:

- Efficiency: It operates continuously, ensuring a consistent supply of charcoal.

- Resource Efficiency: This technology maximizes the use of raw materials, reducing waste and conserving resources.

- Environmental Benefits: The pyrolysis process produces fewer emissions compared to traditional charcoal kilns, making it an environmentally friendly option.

- Consistency: The controlled process results in charcoal with consistent quality, which is crucial for various applications.

- Versatility: The machine can handle various feedstocks, allowing for flexibility in charcoal production.

Applications of Charcoal Produced by the Charcoal Maker Machine

The charcoal produced by the charcoal maker machine finds applications in diverse industries and areas:

- Cooking and Heating: It is a popular choice for domestic cooking and heating due to its clean-burning properties.

- Barbecue and Grilling: High-quality charcoal is prized for its ability to provide consistent and high heat for grilling and barbecuing.

- Industrial Processes: Charcoal serves as a reducing agent in metallurgical and chemical processes.

- Water Purification: Activated charcoal, a derivative of charcoal, is used in water treatment to remove impurities.

- Agriculture: Biochar, a type of charcoal, is used as a soil conditioner to improve soil structure and nutrient retention.

The Future of Charcoal Production

As the world seeks sustainable alternatives to traditional practices, the charcoal maker machine stands as a testament to innovation in the charcoal industry. Its efficient and eco-friendly approach not only reduces the environmental impact of charcoal production but also ensures a steady supply of this valuable resource. With ongoing advancements and increased awareness of sustainability, the Beston Group charcoal maker machine is set to play a pivotal role in shaping the future of charcoal production, where efficiency meets environmental responsibility.