Tyre recycling and disposal is a business with huge demand but very little supply. As such, making it your primary or side business will almost certainly give you a decent income. Of course, as with every business launch, to succeed, you need to it properly. That’s why in this article, we are going to share information on how to launch your own tyre recycling plant.

Steps to Launching Tyre Recycling Business

1. Understand the Market

The first step is to identify prospects for the materials you plan to recycle. Also, find a suitable pyrolysis machine for sale. This states the kind of equipment to buy and the recycled products you will offer. Industrial heating and incinerator plants utilize rubber crumbs for tyre-derived fuels. Besides that, you can also get carbon black and steel wire, which can be sold as well. There are also some different uses of rubber products. For example, road construction companies require shredded rubber crumbs to combine with hot asphalt. Recycled rubber provides a robust surface for areas like running tracks or playgrounds. Not to forget the most obvious application, producing new tires.

2. Find a Site

The next step is to find a rural or industrial location where you can get, store, and process huge numbers of tyres in a safe manner. Tyre recycling is a dusty and noisy process, and so, you need to check zoning and noise restrictions in the region. The location needs to provide easy access for trucks delivering the waste material and collecting the recycled ones. Make sure you have proper fire prevention measures and fire fighting equipment on site.

3. Get Permits and Licenses

It is imperative to check your region’s requirements for tyre recycling plant to avoid getting into legal trouble. Each state has varying licensing guidelines with varying requirements for financial assurance, registration, storage, processing as well as tyre pile clean-up, according to the EPA (Environmental Protection Agency). You may also need to get permits pertaining to fire safety, public health and air quality.

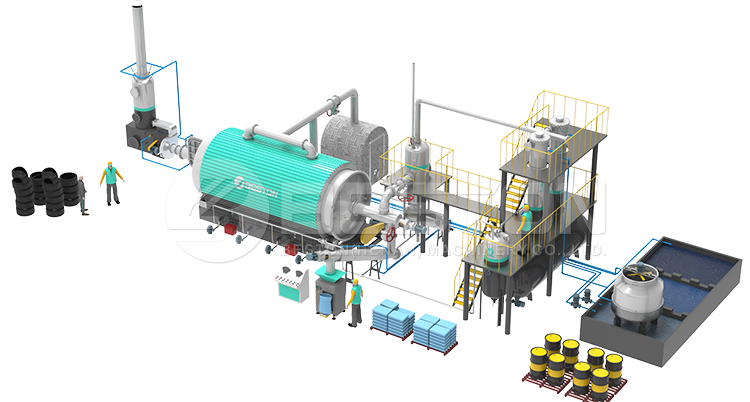

4. Set Up the Tyre Recycling Plant

Buy or rent used or new pyrolysis equipment for processing waste tyres in your tyre recycling plant. To handle incoming materials and tyres on-site, you’ll need to invest in a forklift. You will also need a tyre shredder with a set of varying size screens in order to meet your clients’ specific needs. Large-scale shredders tend to incorporate industrial magnets that separate metals from rubber, thus maximizing the recyclable products. You’ll also need to get containers for storing the recycled materials. You can find tyre pyrolysis equipment for sale here: https://bestonasia.com/waste-tyre-pyrolysis-plant/.

5. Find Sources of Feedstock

It goes without saying that a constant source of used tyres is vital to your recycling business. So, reach out to companies or organizations that need to dispose of vehicle tyres, including tire retailers, car rental firms, service centers, taxi firms, bus & coach operators, trucking and logistics firms, as well as organizations with fleets of vehicles.

Consider listing your facilities in local business directories in order to promote your business. You can also leverage the power of social media marketing. If you provide a used tyre collection service, aim to create a supply base within a radius of 150 miles. This is the recommended distance for a profitable tyre recycling plant. If you want to know more about tire recycling business profit, please check the link here: https://bestonasia.com/tire-recycling-business-profit/.