The creation of pyrolysis technology has really change the way that we are able to process rubber tires. Over the last century, tires have become a significant problem. There are billions of them that are now sitting in landfills. Due to the way they are constructed, and the material they are made from, it is not advantageous to have them in the soil at all. Therefore, something needed to be done in order to eliminate this problem. This is why tire pyrolysis plants( planta de pirolisis de llantas) were created. This is how you can benefit, and also help the environment, by investing in a tire pyrolysis plant today.

What Countries Offer These?

The countries that offer these are numerous. Although not every country in the world will have them, locations such as the United States, China, and even India will have them for sale. If you happen to be in those countries, you will be able to find someone that is local that they offer you a special deal. What you’re looking for, however, is a company(Beston Equipo De Maquinaria Cía. Ltda.,) known for producing the best pyrolysis plants in the industry. Even if it take some time to arrive due to how far you are away from the manufacturer, it is always a good idea to use the very best pyrolysis equipment.

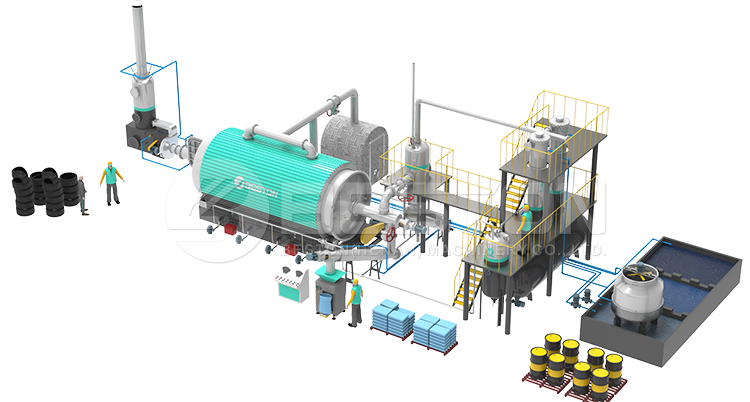

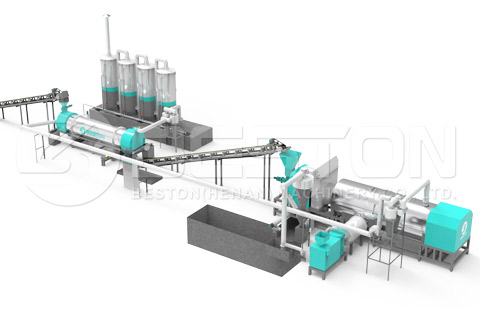

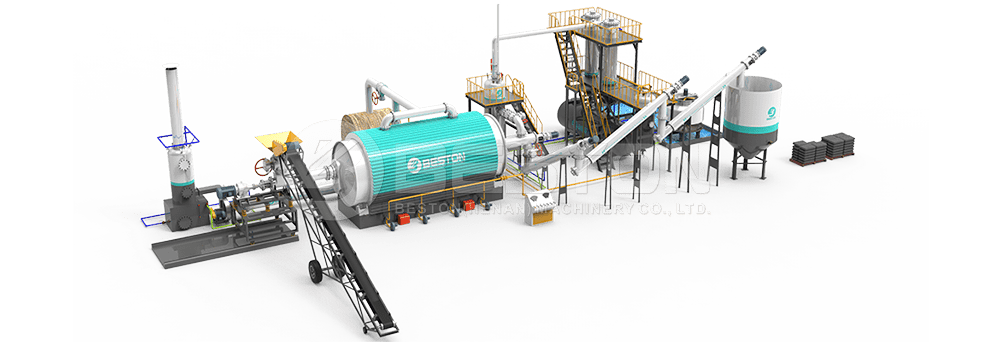

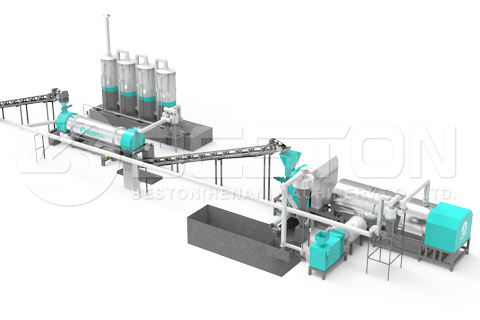

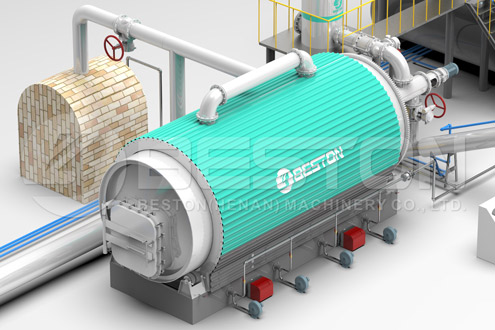

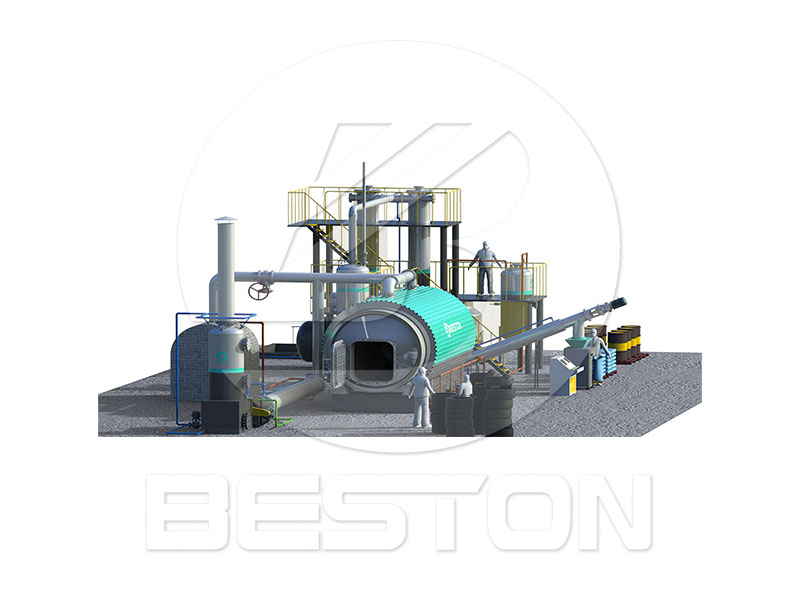

How Are The Tires Processed?

These are often processed in the same exact way, regardless of how the plant is set up, or from what manufacturer you obtain one. Initially, the tires must be broken down into smaller sizes so that they can more easily go into the pyrolysis reactor. These are either placed in manually, or by a conveyor belt, after going through some type of cutting a chipping device(https://www.bestoneco.com/trituradoras-de-llantas/). You will then want to seal the unit, extract the oxygen, and turn the machine on so the reactor can begin to increase the heat inside. The finished product is either going to be charcoal and biofuel, or it may include bio oil as well. Once this is done, you will have the ability to start selling this material and this can benefit your company significantly.

What If You Don’t Have A Large Source For Rubber Tires?

Even if you do not personally have access to a landfill with rubber tires(equipos de pirolisis), you can always access them by working a deal with the local business. If you happen to be connected to a municipal solid waste company, or if you know someone that is there, they may want to consider working with you on this type of project. It is a win-win scenario for everyone involved. There will be enough material to use and also sell to businesses in the general public.

Investing in a tire pyrolysis plant that is currently for sale could be a very wise decision for your business. It is important to have access to a large amount of rubber tires, something that you can obtain from landfills or a municipal solid waste company. Once it is set up in fully functioning, you will have access to a plant that can produce a substantial amount of burnable fuel. It’s a great way to reduce the amount of tires currently being processed and buried in the ground, and at the same time, generate revenue through your efforts. have a peek at this web-site: https://www.youtube.com/channel/UC7h0NREooG-Bca4mZJjbZZg