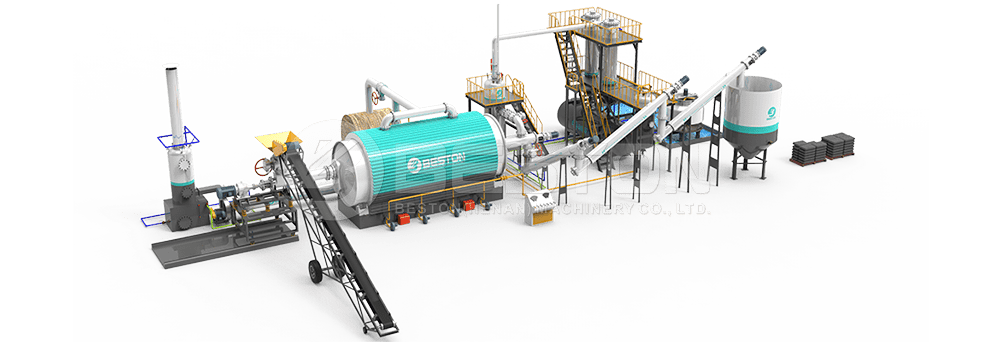

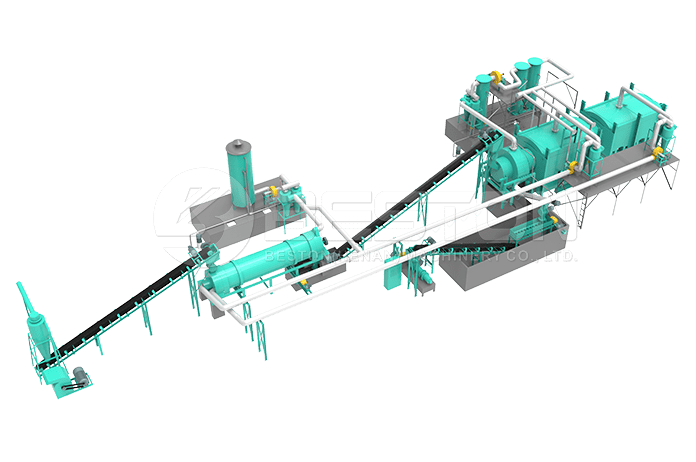

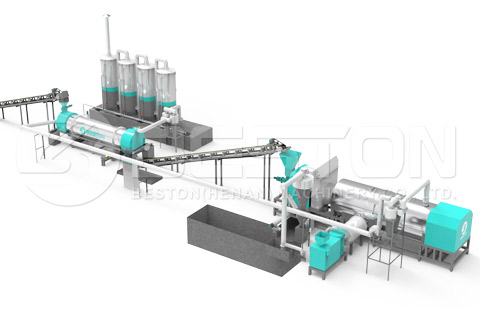

The charcoal production plant is a valuable piece of equipment that can make you a lot of money. This machine is a great investment for any business and it ensures that you can make money fast. When you need a machine you can count on you can’t go wrong with this machine. Read on to learn the top features of a charcoal making machine and why you need to invest in one. View charcoal making machine price.

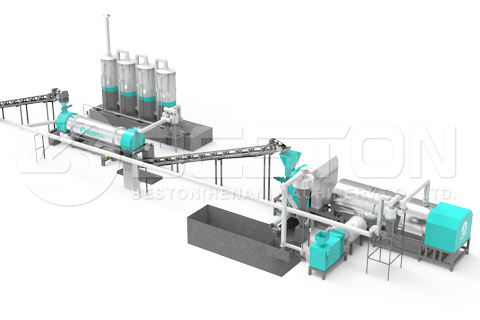

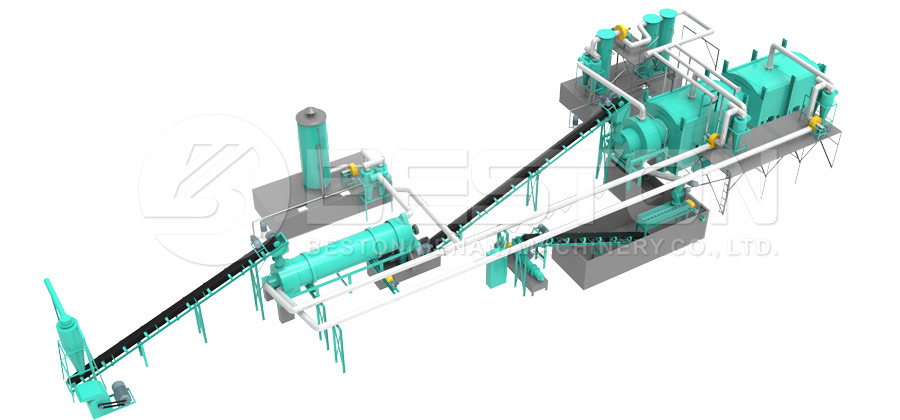

One of the top features of this machine is that it takes waste biomass and turns it into charcoal. The machine can use many different types of biomass which is free or readily available for an affordable price. The biomass is often coconut shells or palm kernel shells. The biomass is affordable or it is even free so you won’t have to spend a lot of money to buy it.

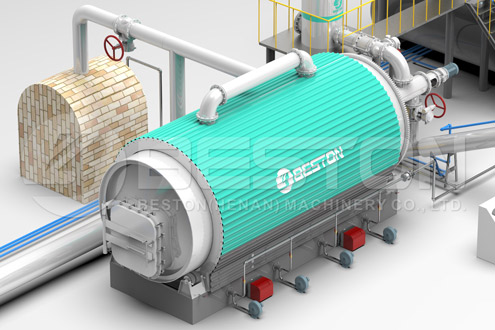

The machine is very efficient and it doesn’t cost a lot of money to run. It uses electricity and gas sparingly which means that you won’t have to spend a lot of money on your utility bills. The machine takes the biomass and heats it up to a very high temperature where it automatically converts into charcoal.

The charcoal is often used for heating and it is also used for cooking and shisa. This wood charcoal making machine is known for being very good for the environment. The machine also takes all of the waste biomass out of the environment which makes it a great choice when you need to do something good for the environment.

The machine takes 95 percent of the volume out of the landfill which makes it a valuable addition to any recycling plant. The cost of the machine is very affordable and it comes in a variety of sizes so you can easily choose the size that is the best fit for your needs. You have a lot of options when you are looking for the machine and you should always work with the manufacture so you find the machine that is the best fit for your business.

The manufacturer can help you in many ways. They can even install the palm kernel shell charcoal making machine and set it up for you. Buying this machine is a great investment and it can help you in so many different and interesting ways. This machine is a great investment in your business and it can help you make a lot of money. It is great for the environment and it reduces all of the biomass in the landfill.