If you’re thinking of investing in a tire recycling machine, you have come to the right place. In this article, we will discuss various advantages of investing in a tire recycling plant and how to go about choosing the right tire recycling machinery to set up a strong foundation for a long-lasting and profitable business venture.

Benefits of Tire Recycling

There are several advantages of investing in a tire recycling machine. One of the biggest advantages is that there is no lack of a raw material. Tires are available in abundance and you can easily get whatever amount of waste tires you want to process. The only thing that matters is the demand and what you can do to fulfill that demand.

It is also an environmentally friendly business. You can sleep good at night knowing that you have helped the environment and in the process, also made quite a bit of money. While tire recycling is a profitable business, the profits depend a lot on the technology used in the process and how efficient are the machines and business processes. Click here to know more: https://bestonpyrolysisplant.com/.

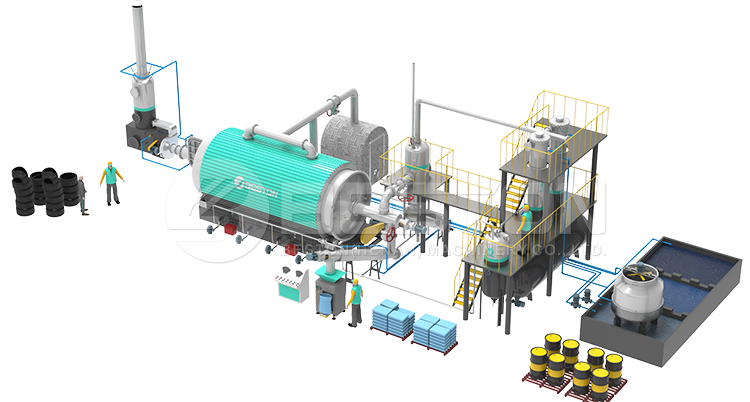

There is a huge demand for the products obtained through tire recycling. Recycling can be done by cutting waste tires down into extremely small pieces. These are used in making play areas for kids and these are also mixed in the material for making roads. The other way to recycle tires is through pyrolysis process. Pyrolysis process breaks down tires into fuel oil, carbon black, steel wire and gas. All these end products have a huge demand which means you shouldn’t have any problems in selling these products.

Choosing the Right Recycling Machine

One of the most common mistakes made by first-time business owners in this industry is that they expect all the machines to be of similar quality but unfortunately, that is not true. Many companies have entered this space due to the huge demand but not everyone has the expertise to build a long-lasting scrap tyre pyrolysis plant.

Many of these companies selling recycling machines often borrow designs from their competitors but are unable to replicate their manufacturing process which often leads to compromises and lower quality. In short, you can’t buy any machine with your eyes closed. You have to do your own research.

The first thing you should look at is the customer reviews of various manufacturers. You should be able to find customer reviews on various discussion forums and even your favorite social media platforms. Search online to discover hundreds of customer reviews. It will help you in avoiding manufacturers who are good at marketing but their products are not really up to the mark.

Once you have chosen a few good manufacturers, take a good look at their product portfolio. Talk to their sales team and discuss the kind of machine you want and what your expectations are in terms of efficiency, capacity, automation and other important things. Most of these companies will also help you prepare a well researched business plan. They will also send engineers for installation as well as for training operators to allow you to quickly get running.

To conclude, there are a number of advantages of investing in tire recycling business. However, it is a competitive business and you need to invest in the latest technology in order to stay competitive and build a sustainable business. Why not visit the site: https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-cost/.